Is there a future for an infrastructure career?

Written by CD, updated May 31 2019 in accordance with our editorial policy.

With a push for innovation and automation, and with continual need to be operated and maintained, a lifelong career can be built out of working on infrastructure. If you can innovate, automate, or operate roads, rail, bridges, tunnels and other infrastructure projects, you will have a good career.

- What is infrastructure

- What do the jobs look like now

- What will be the jobs of the future

What is infrastructure

Roads, bridges, rail, tunnels, sewage, electricity, lighting, parks, schools. We are talking complex systems assembled in the built world to help lots of people accomplish something.

Infrastructure can be funded by the government, the private sector, or a mix. Privately funded infrastructure is built when there is an accountable profit available, such as when revenue is guaranteed by a resource (e.g. oil) or by a government via a public-private partnership. When the benefit of infrastructure is economic, such as the ability for people to get to their destination quicker, it is often funded by government.

What do the jobs look like now?

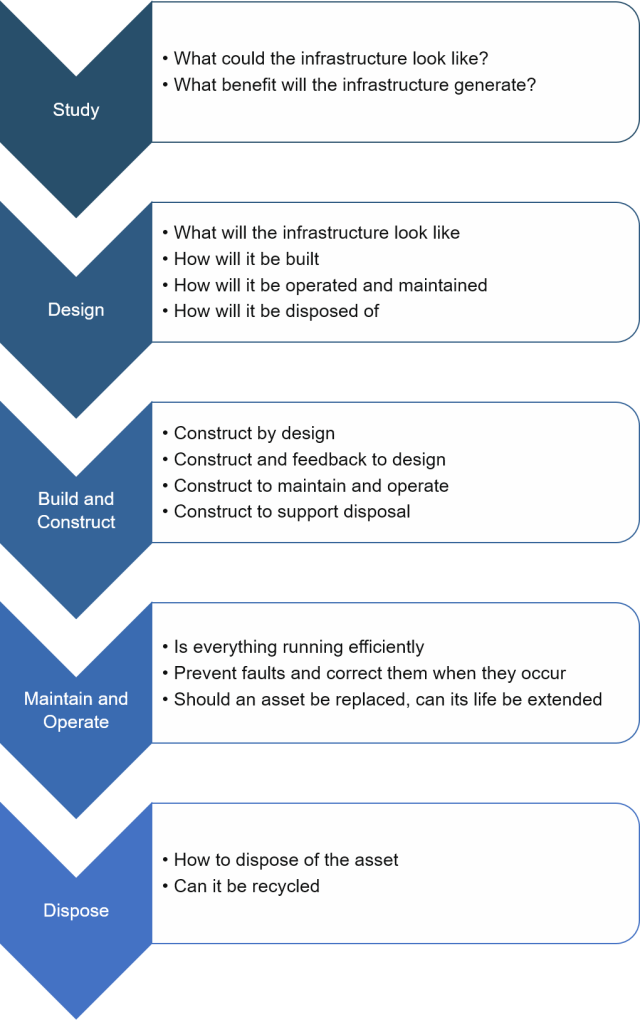

From study to disposal, the life of an infrastructure project, and all the jobs it generates, follows a simple model:

The jobs I like to think of as construction get involved at the design, build and construct (naturally), and operations and maintenance stages.

At each of these stages, what do the jobs look like currently?

Design

Copy and paste from the last project. I’ve seen design managers strive to find the balance between consistent factory style copy and paste design production, and tailored detailed design bespoke for the particular project. Copy and paste design is efficient, but doesn’t leave much opportunity to innovate for the remaining phases. Clients demand efficiency and lowest cost, innovation is tough.

Construct

A man digging a hole with a shovel is still a man digging a hole with a shovel.

You get your hands dirty; you pour in your blood, sweat, and tears; you build something from raw materials; you stand back and admire it when it’s done.

Sure we have machines to help us reach heights, machines to help us dig holes, and machines to help us lift heavy things, but at the end of it, it’s still a person on the site getting the job done.

Construction is a great employer however: Whether you left school at 15 or you have a PhD from a top university, there’s something you can do to help construct infrastructure.

Modular construction is the first step in a new direction.

Maintain

Run it until it breaks; fix it when it does; replace it when it can’t be fixed. Try to stop it breaking down in the first place.

Trying to stop it breaking down is preventative maintenance. Replace lubricant, clean parts, take a look and see if you can spot anything that might break in the future. Knowing how to spot a potential problem is a skill that’s tough to teach, but this is a valuable skill you can learn on the job and keep you employed for years to come.

Fixing something when it breaks down is corrective maintenance. Is it simply turn off and turn on again like tech support; does a part need replacement; do you have the replacement part; do you have the right tools to replace or repair it. These are the problems of corrective maintenance. It’s further specialised than preventative maintenance. If you can keep ahead of the problems and really understand your systems, this is a great career: Things will always break down and need repair, at some point a human will always be required for repair.

What will the infrastructure jobs of the future be?

Innovation

Can you think of a new way to do something?

A new product. You can think of new tools that will do the job better. You have a solution to a problem that people will buy from you. Your product provides better value than anything like it out there. A new product is a great way to innovate:

- Get a lot of experience working on something,

- Identify a ‘gap’ - a better way of doing it,

- Come up with a product that is that better way,

- Get people using it

A new method. Whether you’ve been doing something for a week or for a decade, you might have developed a new way of doing something. Use new tools, use a different material, or even change the order in which your task is done. As you progress through your career, keep your mind open to these new ideas. Holding back innovation at the moment is an unwillingness of those more senior to be open to change. Remember though that show by doing is better than show by telling.

A new system. Why stop at just one method? Can you see a way to change the way everyone works together, can you see a way to make it better? The tough one here is convincing people that your way works, but if you can you reinvent and disrupt entire industries.

Innovation is the constant drive of improvement. Those who can innovate will do well in the future; those stuck in their ways will be left behind.

Automation

Whenever you find yourself doing the same task over and over, ask yourself, can a machine do this? The machine can be plant, a computer, or even a simple tool. Even with years of experience, there is still a small chance a human might make mistakes; for a machine, that chance is much smaller still. If a human’s repeating a task over and over, perhaps a machine could do it better.

Get the machine to do it

If computer programmers do this in the office, why can’t we do it on the construction site?

Mastery comes from practice, but once mastered, how much repetition is really necessary? This is the opportunity to automate. When you know…

- How to do the task,

- What complete, correct, and good quality mean, and

- How it can be broken down into machine achievable steps.

This is when you can get the machine to do it. Humans will still be involved. Someone will need to install, operate, and maintain the machine.

If you automate a task, you can get it done quicker, and you can do more work or sell at a cheaper price (to encourage more customers).

Better ways of working

You don’t need to write build a software suite or write some killer algorithm. There are plenty of small ‘automations’ you can do in your current job right now. These will speed up what you do, and let you concentrate on the more important stuff such as solving the problem.

Take the example of CAD. How often do you repeat the same task over and over when making drawings with CAD. Sure you can write a macro or procedure to take care of it, but you still end up doing a lot of manual click and drag sort of work. The discipline I was in had designers do their own drafting, as the drawing was comparatively easy. If we can automate more CAD tasks, this may be the way of the future for all designers.

Operate and maintain

Most people tend to focus on the design and construction aspects of a project and neglect the huge amount of money spent operating and maintaining it. A bridge looks flashy and expensive when it’s built, but unless you’re in the industry, you tend to forget the work that goes into replacing bearings or resurfacing the deck.

Infrastructure can be designed for low maintenance, but low maintenance does not mean no maintenance. Maintenance free is a concept many infrastructure owners seek, however it is often not possible to achieve. Cost effective maintenance, cost effective over the lifecycle of the project, is the goal.

There are many ways to get involved with cost effective operations and maintenance. People need to plan for it at every stage of the project (except, well, disposal). Think about operations and maintenance as you design it, as you build it, and of course as you maintain it.

Drone use, for example, is changing the way bridges are maintained. I’ve seen a couple of people stand safely on the ground and fly a drone around a bridge taking pictures. No longer do they need to strap themselves up to the bridge at height and inspect it, the drone does all the heights work for them.