How trains change track and how they know which track to choose

Written by Chris, updated Jun 11 2019 in accordance with our editorial policy.

Trains change track using a machine that switches the direction of the rails. The switch or point machine moves blades of rail into place that change the direction of the train wheels. Deciding which track a train should use is the job of the train controller, though it is usually handled automatically by computer.

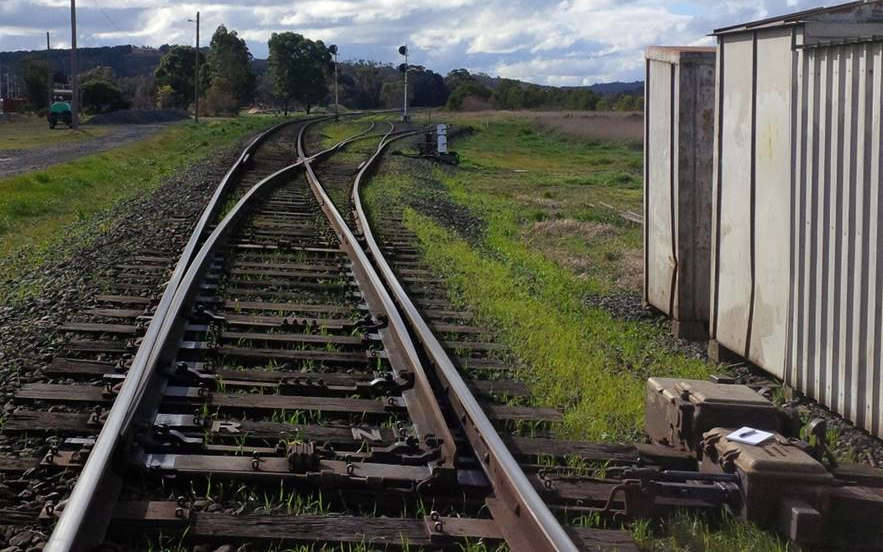

Trains often have to choose a path. Source

Trains often have to choose a path. Source

The machine that switches the track

There are two blades that force the train wheels to diverge from their current rails. If the blades are pushed in one direction, the train will diverge away from its current path. If the blades are pushed in the other direction the train will stay on the straight.

A machine sits near these blades to drive them to either let the train through on, or switch it to the other track. This is called a point machine or switch machine depending on which country you’re in.

Most of the machines I’ve worked with are electromechanical. These machines use electric current to drive motors that move the rail blades back and forth.

You can also find pneumatic machines that use pressurised to force the blades into position. An electric current controls the flow of air.

Both types of machine have mechanisms to figure out which lie the blades are in. This means there is one electric circuit to control which direction the train is going to go, and a separate electric circuit to detect which direction the machine is set to. If the direction is not set correctly, the machine can signal to the train that it cannot proceed over this point.

How do the trains know which track to choose

The control centre chooses the track for the train. Usually the control centre knows which route the train is going to take. A computer is programmed with that route, and the computer tells the machines which way to push the blades. Once the blades are in place, the train is allowed to move over the top and continue straight or diverge.

Selecting the right track is also a matter of safety. Before changing the track the train is running on, the system must check to make sure it’s safe. A train is not allowed over the top while the blades are moving. And to the best of its knowledge, the machine cannot be used to direct one train into another.

Some machines can be operated manually with a lever. Train drivers can select or override the path that they want their train to take. To keep the system safe, the train drivers are usually in communication with a controller for the region of the network that they are on. I’ve most often seen the manual mechanism in depots and sidings.

Signalling is the system that directs trains on their tracks and prevents them from crashing. If you’re interested in signalling, including what jobs there are directing trains, check that out here: https://econstructioncareers.com/news-insight/rail-signalling

How do trams switch tracks

Trams switch tracks using the same machines that trains do. A machine uses an electric motor or a pneumatic system to push rail blades around and direct the trams. The only difference is the control decisions for which direction the tram should take.

Because trams can stop quickly, they can change tracks without worrying as much about hitting another tram.

The control can be provided by the same traffic light system that cars use, by a remote control centre, or even by the tram itself. A lot more onus is on a tram driver to know which way the tram has to travel.

What can go wrong?

Collision with another train

If a train is sent down the wrong track, it can collide with another train. To stop this happening, the computer controlling which track the train takes makes sure the track ahead of the train is clear before diverting the train down that path.

Derailment

A train sent down a wrong track has two opportunities to derail: One if the machines are not set properly, and the other if there is a purpose built derailer designed to push the train off the track to prevent a collision.

Derailing a train is safer than having it crash into another one, better chance of survival.

Whose job is it to keep everything switching properly?

Many signal failures are failures in the machine that switches track

Maintaining the machine is usually the job of the signalling engineer.

Maintaining the rail blades is usually the job of the permanent way engineer.

Too often I’ve seen arguments about whose job it is to look after this system. Some rail operators even form special teams of people whose sole job it is to maintain the machines and blades.

The machine needs to be cleaned and lubricated regularly. The blades need to sit against or away from the rails at the correct gaps - the wrong gap may lead to damaged wheels, bent rail, or derailed trains. The rods inside the machine need to be set appropriately.

Part of maintaining the machine is to test to make sure the motor works pushing the blades to both positions. Watch out though, there are more than a few stories of maintenance engineers who have lost fingers because the motor pushed the blade against their hand while they were working on it.

If you’re interested in reading more about what these jobs are, take a look here.

Changing the track of a train is a lot more complicated than changing the lane of a car. It involves complicated machinery, electric circuits, and safety protection. If you’re interested in working with this sort of machine, the jobs available are as a signalling engineer or a permanent way engineer.

Related post:

- Signalling is the system that directs trains on which route to take, and ensures the trains are doing so safely. To understand what signalling is, and how it prevents trains from crashing, check this out: https://econstructioncareers.com/news-insight/rail-signalling