6 Concepts Essential for Understanding Signalling

Written by Chris, updated Jul 31 2019 in accordance with our editorial policy.

Rail signalling is the system that tells trains where to go while preventing them from crashing. I’ve put together this list of some of the terms I believe are essential to getting started in understanding rail signalling.

1. Track Circuit

An electric circuit that uses the rails to detect the absence of a train. The circuit detects when a train is not in a section of track.

Track circuits figure out where trains are, and where trains are not!

Track circuits figure out where trains are, and where trains are not!

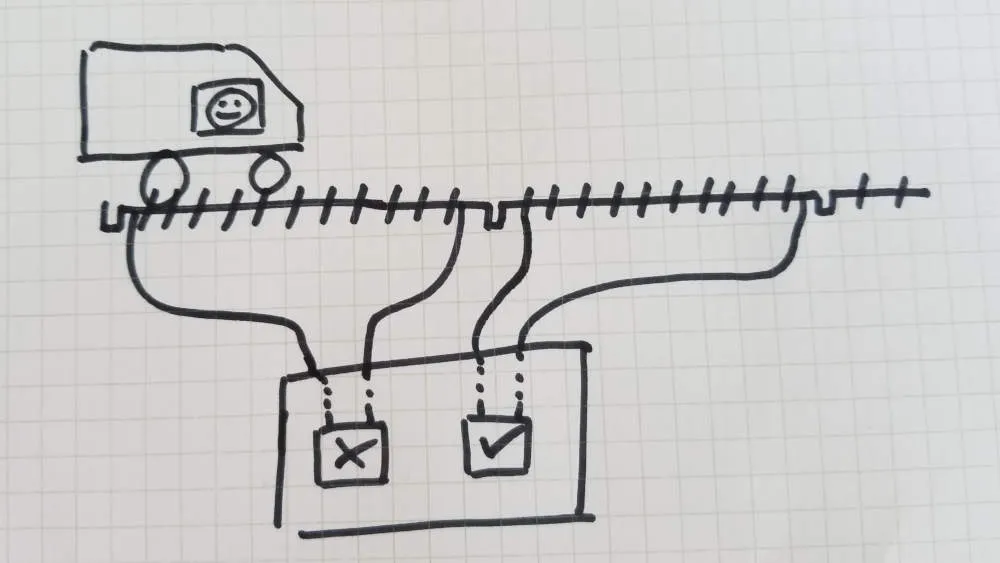

Track circuits run an electric current down the rail which is detected at the other end. If the electric current doesn’t reach the other end, the track circuit tells the signalling system a train is in that section. Metal wheels and axles on the train short circuit the current and it never reaches the other end.

Why does a track circuit tell you were a train isn’t rather than where a train is? By only knowing the track is clear only when the current is received, if the current is not received - such as in a power failure - the signalling system knows that it cannot be sure there is no train on the tracks.

This is how trains avoid collision. If you’re interested to find out more about how trains avoid collision, check this out here: https://econstructioncareers.com/news-insight/how-trains-avoid-collision

2. Point detection

Point detection answers the questions about the point at which trains diverge:

- Which direction is the track set in?

- Are the moveable blades correctly aligned to allow the train through?

Knowing which direction the track is set in is essential to the rail signalling system, this is how trains are directed.

If moveable track blades are not correctly aligned, trains can derail. The machine that moves the blades of rail to switch the direction of trains can also detect where the blades are. If the moveable blades aren’t within a few millimetres of the fixed rail, then the train wheel might derail. Detecting the position of the blades is vital to safe train movement.

Luckily trains don’t derail very often due to misaligned point or switch machines. I analysed some data recently to find out why trains derail, you can find my results here: https://econstructioncareers.com/news-insight/why-trains-derail

3. Automatic Train Protection

Rail signalling prevents trains from colliding with each other. Automatic Train Protection is a function that prevents trains colliding automatically.

The Automatic Train Protection system will trigger a trains brakes automatically if it believes the train is about to enter an unsafe situation - a situation where it can collide with another train or derail from the tracks.

By forcing a train’s brakes to apply, Automatic Train Protection ensures trains do not collide.

To force the train’s brakes, the automatic train protection system can include a device by the side of the rails, or a device on board the train. When the signalling system determines it’s unsafe to proceed, the automatic train detection devices in the area are set up to transmit to any approaching train that the train must apply its emergency brake. This ranges from a mechanical lever, to magnets, to short range radio transmissions.

4. Interlocking

An interlocking is the connection between the information about track circuits and points detection is transmitted to the train and the automatic train protection.

The interlocking is a set of logical rules that dictate the direction and the ability of a train to move forward in to the next section. Interlockings do not drive the trains, but the interlocking is responsible for calculating where a train can drive.

Old fashioned interlockings are made out of mechanical levers. The most interesting mechanical interlocking I’ve seen still working today is in Melbourne, Australia where trams cross train lines. Overhead wiring for the tram is interlocked with the overhead wiring and signalling for the train; a train is not allowed to cross the tram line until a mechanical lever has changed the overhead wiring to the train system.

Modern interlockings are computer based. Computer based interlockings are computer systems that take inputs of track circuits, point detection, and other safety features of the network, and calculate where trains are allowed to go. Programming of a computer based interlocking is often done in special languages that are easy to read by signalling engineers, but are hard to figure out by the rest of us.

5. Communications Based Train Control

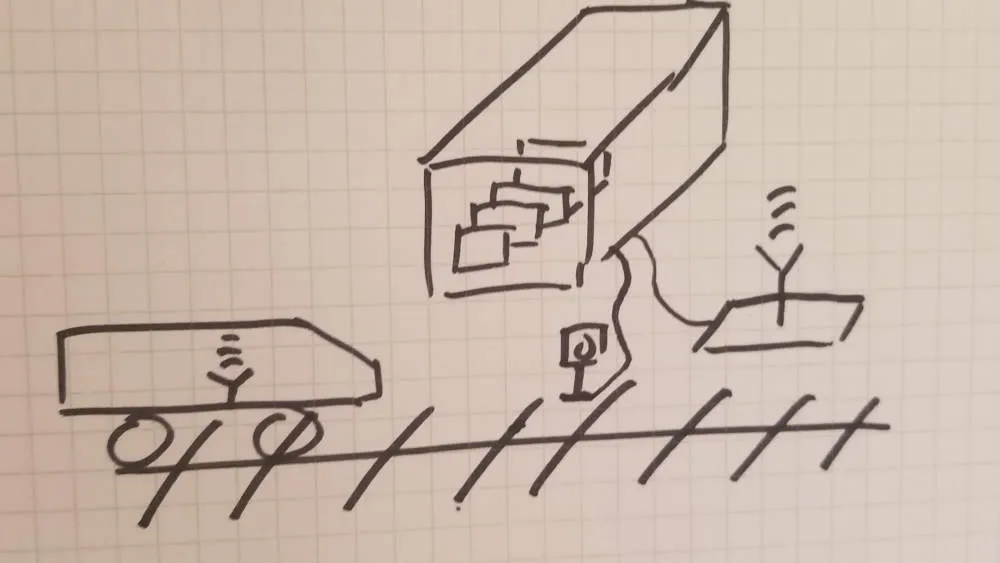

Communications based train control is when a signalling system uses communications, such as Wi-Fi or mobile phone signals, to give a train its instructions about how far it can move forward. This information is interpreted by a human driver or a computer to operate the train. Often communications based train control is combined with automatic train protection; if the instructions are violated, the train stops automatically.

Trains on the track and computers in a room can talk wirelessly to each other

Trains on the track and computers in a room can talk wirelessly to each other

Trains also communicate their position back to the signalling system to allow it to calculate how far ahead the train can move. The train calculates its position by using an odometer, fixed beacons in drilled into the ground at known locations, or by GPS. A combination of all three can be used on one train line, particularly if that line has a lot of tunnels that block GPS.

6. Fail safe

When trains collide, people can die. When equipment breaks down, trains can collide. Fail safe means that when a piece of equipment in a system fails, the system should default to a safe state.

The reason a track circuit detects the absence of a train by measuring an electric current is because it is fail safe. When the electric current is not received, a train might be there. If the signalling system believes there is a train present, it won’t send another train into that section - this is fail safe. If the power stopped working (i.e. the equipment failed) then the electric current wouldn’t be received and the system would think there is a train present - the safer situation.

Fail safe is often why signal faults cause more delays on a rail line than any other type of fault. What is the safest way to prevent trains colliding? Don’t allow trains to move!. If the system cannot guarantee the safety of the line ahead, it will stop any train approaching. A human must intervene and make sure it is safe to proceed, this takes time and can cause delays.

Did you reach this far and wonder why I didn’t include signal in this list? Rail signalling is much bigger than the traffic light coloured signals by the side of the line.

Rail signalling is a big employer of people worldwide. Customers expect trains to run quickly, reliably, and without crashing. Rail signalling facilitates this. Getting a job in signalling can be tough, but it’s a rewarding industry to be in. Signalling is how I started out working in rail.