Why Rail Tracks Have Stones, Explained With Pictures

Written by Chris, updated Jul 16 2019 in accordance with our editorial policy.

Why do rail tracks have crushed stones under the tracks? The crushed stones underneath the tracks are called ballast. Ballast provides a smooth and consistent surface for the tracks, and this means a smooth run for the train. By using crushed stones, rather than say a solid block of concrete, movement due to trains and heat can be absorbed by the stones. It is also easier for water to drain away from the track.

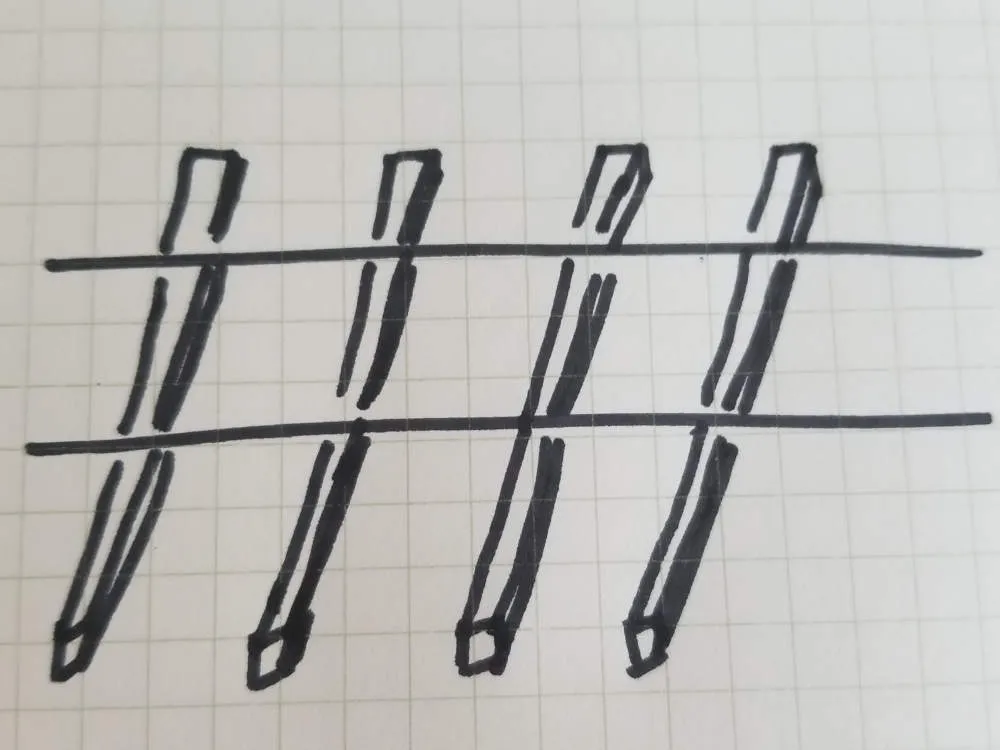

Crushed stones, called ballast, support the train tracks and allow water to drain.

Crushed stones, called ballast, support the train tracks and allow water to drain.

What are the crushed stones alongside rail tracks?

The crushed stones, also called ballast, alongside rail tracks are there to hold the tracks in place as the tracks move with the passage of trains or due to heat expansion and contraction. For rail lines that use certain types of electrical systems in the rails, ballast also provides an insulation between the rails.

Wooden planks or concrete blocks under the rails help the rails stay in position as well. By sitting on crushed stones, these blocks (also called sleepers or ties) and the rail can absorb movements due to heat and due to the passage of trains.

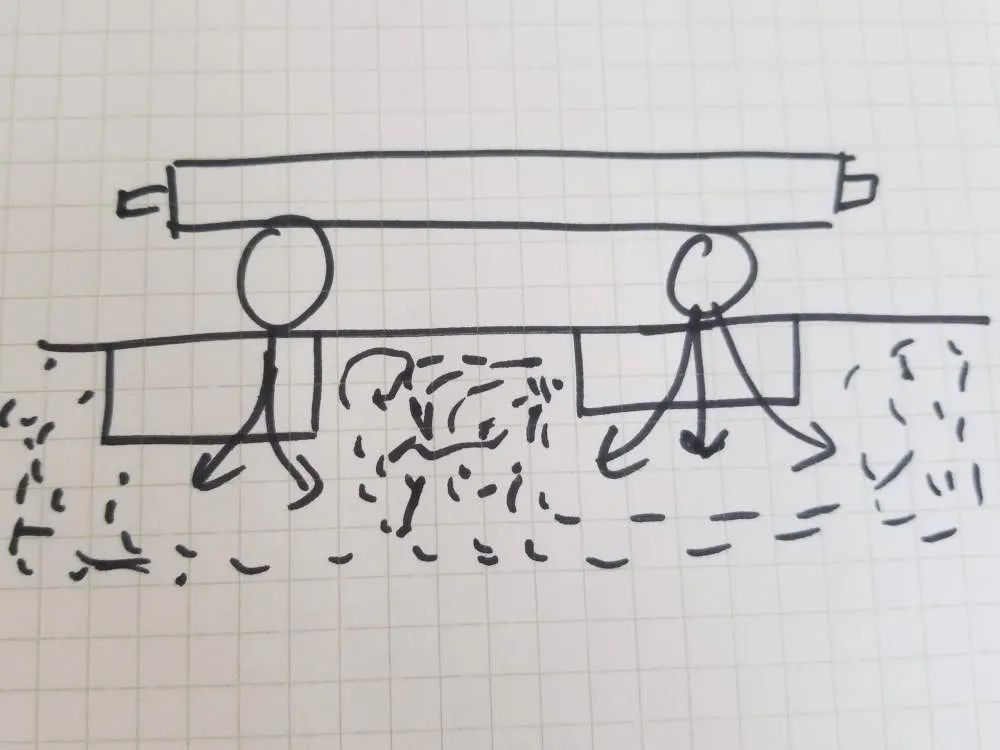

Sleepers, also called ties, hold the rails in place

Sleepers, also called ties, hold the rails in place

The stones also help prevent water from pooling under the tracks when it rains. Water can erode away dirt and stones and make for a bumpy ride on the trains. Fixing the erosion, and the drainage of tracks, is an important job for track maintainers. Click here to find out more about track maintenance: https://econstructioncareers.com/news-insight/track-maintenance

Rails sit on a foundation of this ballast, and other material, to allow for a smooth, consistent, and fast ride for the train above.

What are the stones made of?

The stones, or ballast, are usually crushed igneous and metamorphic rocks. Basalt, gneiss, or granite can be used depending on local availability. All stones are broken and crushed so that they can stay in a compacted position.

What are the wooden planks under rails?

The wooden planks, called sleepers or ties, hold the two rails in place. Heat and trains move rails around and these planks keep the rails held together as they move.

Sleepers also help distribute the heavy loads of the train through to the ballast underneath.

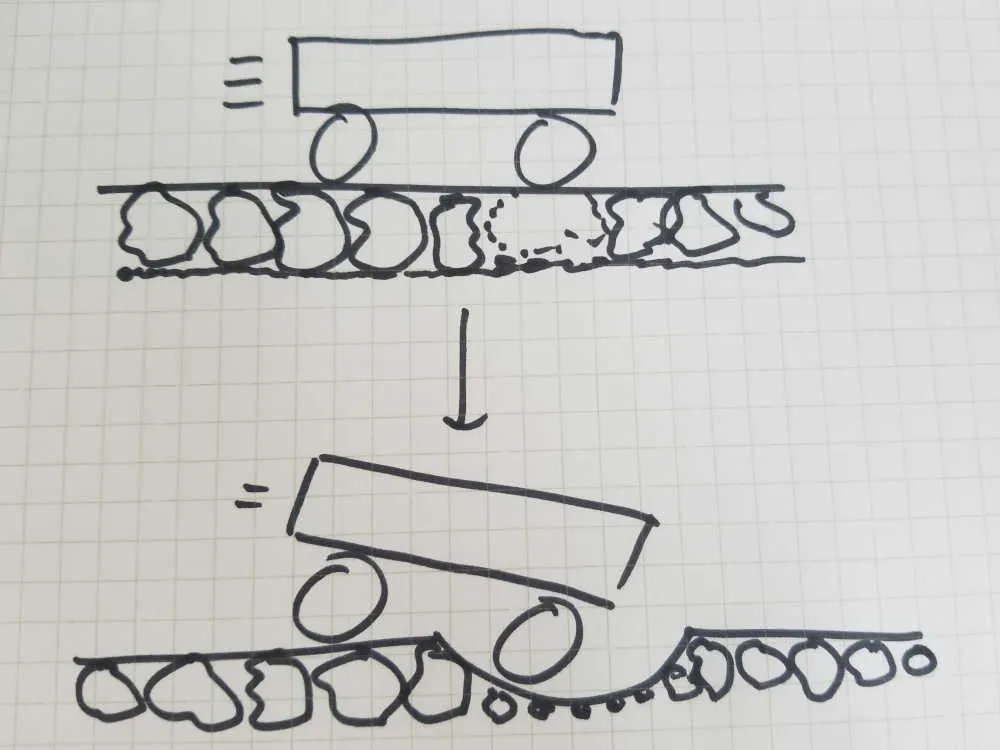

The weight/force of a train is distributed amongst the ballast via the sleepers

The weight/force of a train is distributed amongst the ballast via the sleepers

If sleepers are made of wood, can they burn? I don’t recommend burning sleepers, ties, or using them in a garden. Over decades of use, grease, oil, and other chemicals used on trains drip down onto the sleepers. Wooden sleepers absorb these chemicals which can leach out if they’re burnt or used in a garden. Not recommended.

What are the alternatives to wooden sleepers/ties?

Concrete and steel are the most common alternatives, recycled plastic is becoming increasingly popular.

Concrete sleepers are stronger and last longer than wooden ones, but concrete is more expensive than wood.

Steel sleepers have a long life and are easier to work with than concrete. Being made of metal though, steel sleepers are inappropriate for certain types of electric trains and train signalling.

Plastic sleepers are typically the most expensive. Recycled plastic sleepers are becoming more popular however. Plastic sleepers are easy to work with, have a long life, and don’t interfere with the train electrification.

What happens if ballast and sleepers are neglected and not maintained?

Trains have to slow down or suffer through a bumpy ride if the ballast or sleepers are not maintained. This is because of:

- chipped, cracked, or broken rail;

- wear on the top of the rail;

- gaps in the compacted ballast, the rail sinks into the gap causing a bump when the train goes over - similar to a pothole on the road.

When ballast wears away, trains have a bumpy ride

When ballast wears away, trains have a bumpy ride

Trains can also derail if the condition of ballast, sleepers, and rail deteriorate too much. We analysed a few years of derailment data to identify what the most common causes of train derailment are, and track related problems were on top. Click here to take a read: https://econstructioncareers.com/news-insight/why-trains-derail

How are ballast and sleepers looked after?

Maintaining ballast is about removing the gaps that form between the stones. Gaps can form gradually due to the movement of trains on the rails, or by water flowing through and eroding the stones.

To do this, a machine picks up the rails and sleepers, and re-settles ballast to close the gaps in the rocks. This is also a good opportunity to replace stones that have eroded into rounder shapes.

Sleepers crack or erode after being exposed to weather for many years. To replace broken sleepers, the rails are first untied from the sleepers, then a machine picks up the rail, a new sleeper is inserted, and the rail is lowered back down and retied to the new sleepers. Sometimes it’s cheaper or easier to cut out a section of rail and sleepers, drop a new section in, and weld it back together.

We wrote recently about what is involved in track maintenance, and what sort of qualifications are needed for the work. Click here to check out that article:

Does rail track always have ballast and sleepers?

There are many train lines that do not use ballast or sleepers. Rail can be tied to concrete blocks rather than sleepers, and these blocks ‘float’ a little in the structure that they sit on, similar to a bridge.

Modern subway and metro lines typically use this alternative to sleepers. Concrete blocks have a better life-time performance under the load of frequent trains. Subway and metro lines are also typically in tunnels, the controlled conditions help prolong the life of the concrete which outweighs the greater initial costs.

I used to work as an Alignment Engineer where I helped to design and build train lines. The major part of this job was deciding how to form the ballast, and other materials, that go underneath the rail. We had to make sure that it would be cost effective and withstand harsh environments and heavy frequent trains. I’m currently getting ready for the next project; it’s an exciting time to be building new train lines.

If you’re interested in getting started in rail but unsure of some of the jargon I’m using, check out an article we recently put together about 11 industry insider terms anyone getting started in rail needs to learn: https://econstructioncareers.com/news-insight/eleven-rail-terms