7 Challenges For New Rail Workers

Written by Chris, updated Aug 14 2019 in accordance with our editorial policy.

When I started in the rail industry, these safety concepts required to work on track felt a little confusing. I started as an engineer in projects, but understanding all of these safety points is also a necessity for maintenance workers, drivers, and anyone else who works amongst live rail lines.

I put together this list to try to clear some of the confusion, hopefully you avoid some of the mistakes I’ve witnessed in my years working with rail:

1. Is it safe to be on the track?

When I first started work, there was a lot of information dumped on me about safety. This hasn’t changed. Your first experiences working with rail are all about safety. Where you can stand, where you can’t stand, what you can’t touch, who is responsible for safety, who should you listen to, and all sorts of other answers to questions you didn’t know you needed to ask.

Tunnels, bridges, and tight spaces

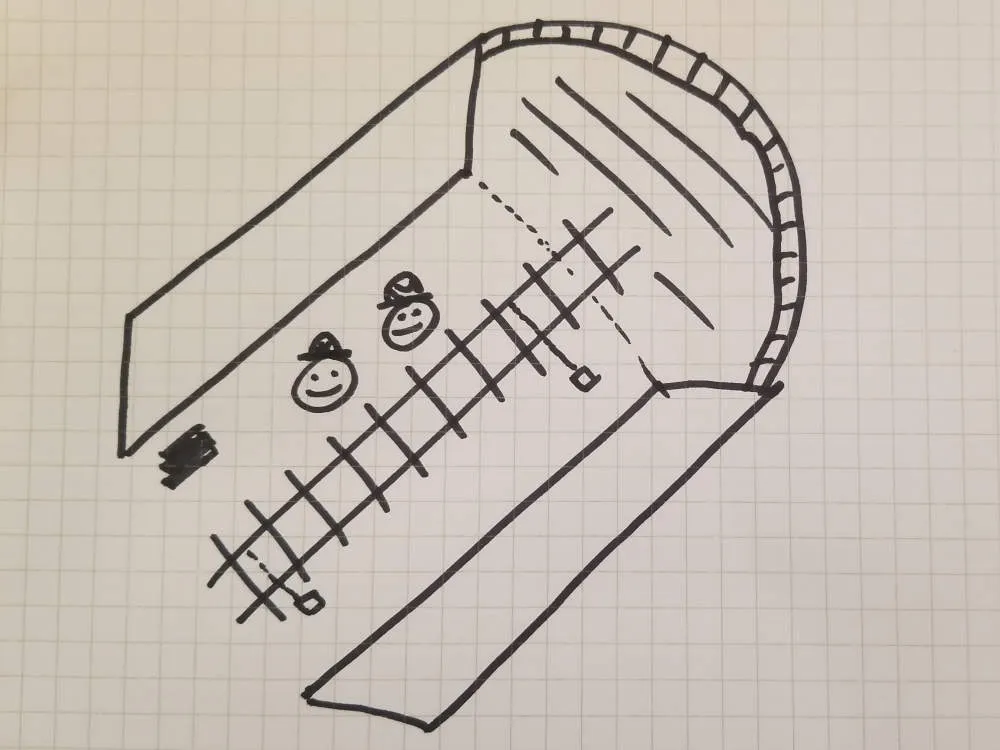

How long will it take you to get out of the way when there is a train coming? If you can’t step to one side to let the train go by, you’re in a restricted area. These can include tunnels, bridges, cuttings, and depots (it’s no good if the ‘safe area’ you can move to is another live track!).

When working in these areas there will be extra safety precautions you need to be aware of. The rules differ by region, but the principle is the same: You need to be sure you can get to a safe place within a certain amount of time. If there is a promise no trains are in the area, you may be allowed more time to get to a safe place. If trains are regularly coming through, you might need someone to give you ample warning so you can make it to a safe place in time.

Working in restricted areas can be dangerous, make sure the right rules are in place before you get caught out.

Working near tunnels and cuttings can be dangerous

Working near tunnels and cuttings can be dangerous

Watch where you’re working

Tools left on the track are dangerous. When figuring out how much time it takes to get to a safe place, you need to include the time it takes to move your tools with you. This includes carts for tools. Hand operated carts aren’t guaranteed to signal to the train it can’t come into this area. You may need to remove them when a train is coming.

If there is plant being used on your site, it’s likely someone has already prevented trains entering the area. It’s hard to get a digger out of the way of an approaching train!

2. What not to touch

Rail is dirty. Trains drop oil, metal dust, and in some countries excrement on to the tracks. Rats also love to live in the equipment housings, using the electricity to keep warm. They leave waste and disease behind.

The tracks themselves are kept smooth for trains to run on. This means grinding the rail. Grinding releases little bits of metal dust into the air. Particularly in tunnels and enclosed spaces, this isn’t something you want to eat. Avoid touching it and then touching your lunch.

Cables are everywhere on a modern rail system. The cables carry information that tells the trains where they can go and when they have to stop. Cables also carry electricity to power trains, communications equipment, lighting, tunnel ventilation fans, and anything else electrical that sits next to the train line. Unless it’s your job avoid touching the cables. The insulation on the cables breaks down over time. You might get electrocuted, cause a train to derail, or cause two trains to crash.

3. How to not disrupt running trains

Delaying trains is bad. Operators can fine the people responsible for the delay (luckily I’ve only seen delays caused by accident, no fines given).

Train control systems

Trains are controlled by a combination of procedures, electric circuits, and computers with different complexities based on where you are.

Any disruption to the train control system will prevent trains from running.

Broken cables, bent wires, dislodged antennae can all cause the train control system to stop working and trains to stop running. If you’re not sure what it does, avoid touching it.

Hand back on time

Most of the time I work on track, trains are blocked from entering. There is a fixed time by which I must clear the track and allow the trains to run again.

Being late disrupts trains.

4. Train drivers can’t avoid people on the tracks

It can take 160m (over 500ft) to stop a passenger train. Freight trains take even longer. This is a greater distance than train drivers can see, particularly when going around a corner. Train drivers can’t go and stop like a car or a bus.

The path that train drivers take is often the responsibility of the operations control. The driver needs to know what the correct path is, but the driver often has little control over which path the train takes.

A train driver can’t do much to stop the train avoiding you if you are working on track. You need to look out for trains, trains can’t look out for you.

5. Where is the electricity

This is the other reason you don’t touch the cables unless you know what you’re doing.

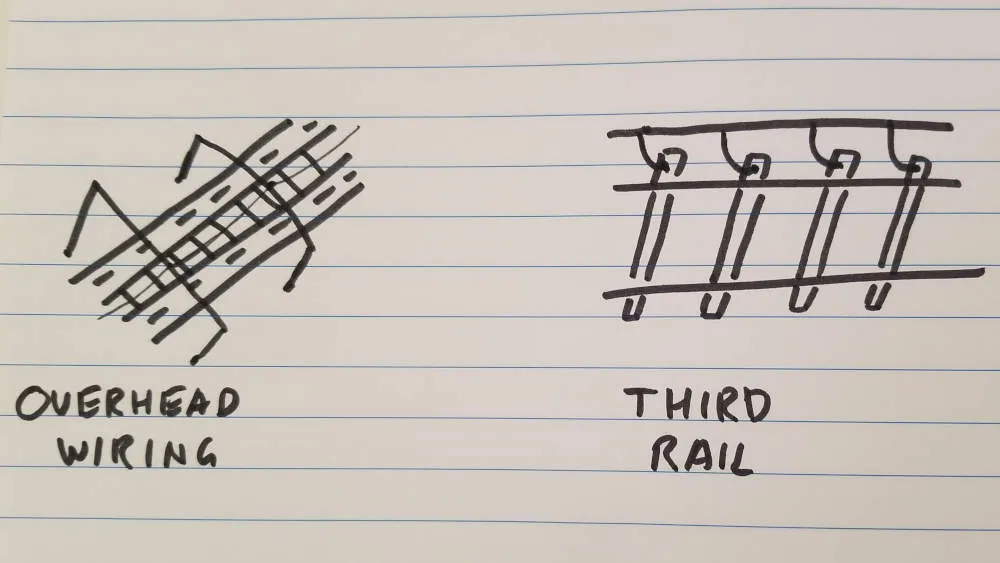

Overhead Wiring

These are the wires that supply trains with electricity from overhead. Most of the time when you’re working on the train line you can’t reach high enough to touch the overhead wiring. This isn’t true if you’re in a vehicle. If you’re operating plant, such as diggers or cranes, watch out for the overhead wiring. Most rail networks will have detailed rules about how to operate plant on the train line, including looking out for the overhead wiring.

Avoid touching the metal structures that hold the wires in place. There are safety systems in place in case you do touch them, but you never know when those systems have failed.

Third Rail

Watch the blue light go out before you step on the rail, I like to avoid it anyway. A third rail is used to supply trains with electricity from the ground, rather than overhead. It’s space efficient for use in tunnels. Make sure the third rail isn’t live before you even stand on it. On some rail networks, you can watch a little blue light turn out as the power is cut, on others someone simply clamps the third rail to its ground (creating a short circuit if the power were to be on).

Overhead wiring is hard to touch, but third rail can be more dangerous

Overhead wiring is hard to touch, but third rail can be more dangerous

Track Circuits

Many rail networks use an electric current in the rails to detect if a train is there. As the large metal wheels of the train pass over a section of track, the current is short circuited to the other rail and the system knows where the train is.

You’re unlikely to shock yourself using on this one thankfully. I knew an engineer who learnt his trade in a tougher era; his way of testing if the track circuit was working was to use the back of his hand to short circuit the connections in the equipment box. By using the back of his hand, the jerk from the shock would move you away from the electricity by reflex. This is not recommended any more.

You might disrupt train operation however. As I said earlier, disconnecting or digging through the wrong cable can disrupt train movement. Track circuit cables positively detect where a train is. If the cable is broken, they can’t tell the system there is no train in that section. Therefore no train will be allowed into the section. Breaking cables causes delays, try to avoid it.

6. Working with trains around

Trains are noisy. People are surprised when I tell them trains are quiet.

When working on track, the only noise you hear of a train approaching is a faint whine in the rails. You have about 30 seconds to clear the track before the train comes through. Good thing there’s often a lookout to give you more warning to get out of the way of an approaching train.

7. If you see a problem, do something

A working rail system is everyone’s responsibility. If you’re out there working and something doesn’t look right, let someone know or if you’re 100% sure you can fix it yourself, do so. I learnt this lesson from my first supervisor. After showing how not to damage the cables, we happened to come across some large branches on the track. They wouldn’t have derailed a train, but they could’ve been kicked up and hit someone as a train went by. After checking it was safe, we removed the branches from the track.

Another time we noticed some loose cabling that was left dangling. It was labelled or marked, and it looked like it had fallen out. This is the sort of thing we can’t fix ourselves - it might have been left like this on purpose. We called it in to the equipment operator and they sent someone out to fix it properly. Some things you can fix, other things you shouldn’t touch.

I had some great supervisors and mentors when I started out in rail. They taught me a lot about what it means to be a good rail engineer. These have been a few of the ways of working I found challenging and interesting when I started; the things that were different from other industries.

Here are some related topics I’ve talked about recently:

- What signalling is, a visual guide to train control: https://econstructioncareers.com/news-insight/rail-signalling

- What track maintenance is and how it still provides great jobs without risk of automation: https://econstructioncareers.com/news-insight/track-maintenance

- How trains drive themselves: https://econstructioncareers.com/news-insight/how-trains-drive-themselves